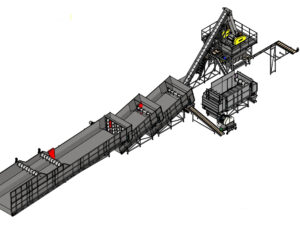

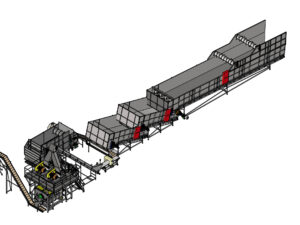

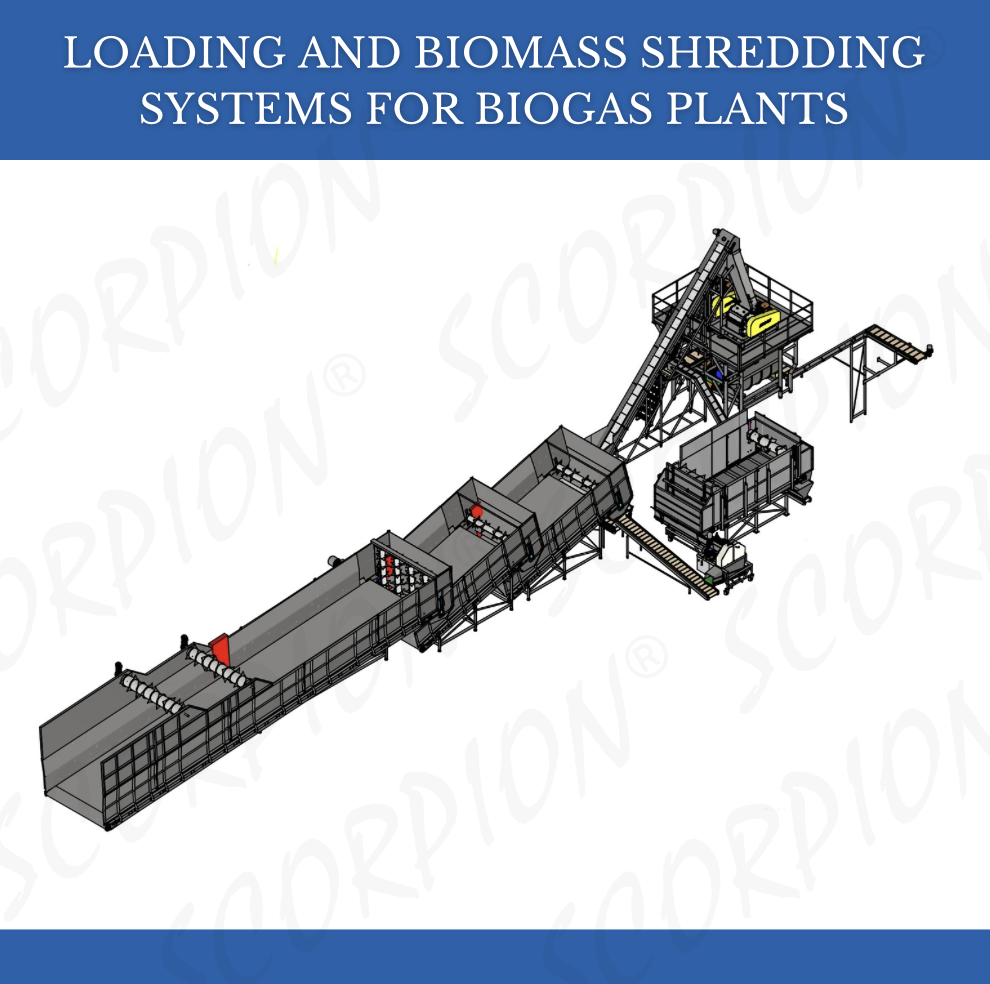

Loading and Biomass Shredding Systems for Biogas Plants

Comprehensive Technological Solutions for the Biogas and Organic Fertilizer Industry

For many years, we have actively supported the development of sectors involved in biomass processing, particularly in organic fertilizer production and the preparation of plant material for biogas plants.

Our loading and shredding systems are designed with investors, plant operators, municipal companies, and fertilizer producers in mind—providing efficient, scalable, and environmentally compliant technologies.

Our solutions include:

- Automatic intake and unloading systems for feedstock, including loading hoppers with the option of integration with warehouse and transport systems.

- Equipment for preliminary and final biomass shredding.

- Fraction homogenization systems with moisture control and component proportion management.

- Metal detection systems to enhance the safety and reliability of the installation.

- Complete plant outfitting with modern, fully automated control systems.

- Automated packaging systems adapted to various forms of end products.

Applications and Benefits

At subsequent stages of processing, raw materials undergo advanced treatment processes to optimize efficiency, improve product consistency, and ensure compliance with environmental standards enabling the production of final products such as:

- Granulated organic fertilizers, a high-value soil amendment that improves soil structure and nutrient content.

- Components intended for reuse in composting or fermentation processes, allowing further breakdown of organic matter and its transformation into valuable products.

- Substrates directed to biogas plants, where anaerobic fermentation produces biogas used for electricity and heat generation.

Our technologies allow for the optimization of production processes, reduction of material losses, and improvement of the overall energy efficiency of the facility.

Thanks to their modular design, the technological lines can be perfectly adapted to the needs of both smaller plants as well as larger industrial-scale installations.

Substrates directed to biogas plants, where anaerobic fermentation produces biogas used for electricity and heat generation.

Our technologies allow for the optimization of production processes, reduction of material losses, and improvement of the overall energy efficiency of the facility.

Thanks to their modular design, the technological lines can be perfectly adapted to the needs of both smaller plants as well as larger industrial-scale installations.

Why Partner with Us?

Each installation involves a unique process, which is why all our loading systems and biomass shredding lines are individually designed to meet the specific needs and requirements of each client.

We offer comprehensive support—from project design, through manufacturing and installation, to commissioning and ongoing service.

Our systems combine innovation, reliability, and environmental responsibility, supporting the sustainable development of the biogas and organic fertilizer industry.

Get in Touch!

We welcome partners seeking modern, automated, and custom-designed solutions for biogas plants, biomass processing facilities, and organic fertilizer producers.

Each installation involves a unique process, which is why all our loading systems and biomass shredding lines are individually designed to meet the specific needs and requirements of each client.

We offer comprehensive support—from project design, through manufacturing and installation, to commissioning and ongoing service.

Get in Touch!

We welcome partners seeking modern, automated, and custom-designed solutions for biogas plants, biomass processing facilities, and organic fertilizer producers.