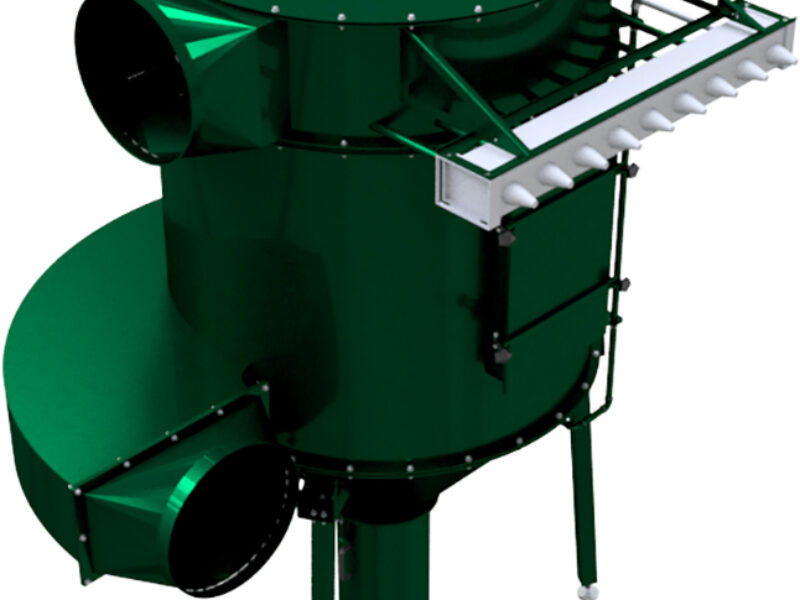

Filtrocyclone

Cyclon dust colector is an innovative device that is revolutionizing industrial air purification processes.

Our solution is widely used in:

- Aspiration installations of machinery and equipment

- Pneumatic transport systems for bulk materials

- Food and other manufacturing industries

Key features and benefits:

High efficiency: effectively removes particulate matter (dust) generated during technological processes. Versatility: adapted to a variety of aspiration and pneumatic conveying plant systems. Flexibility of application: works well in the food industry and other production sectors. Customization : we offer the possibility of manufacturing non-standard equipment on special order of the customer.

Why choose our Filtrocyclone:

- Increases the efficiency of production processes

- Improves air quality in the plant

- Supports compliance with environmental standards

- Offers flexible solutions tailored to individual needs

-

Aspiration installations of machinery and equipment:

- Extraction of dust and dirt generated by production machinery (e.g. grinders, saws, milling machines).

- Air purification in wood, metal, plastic processing.

- Removal of fumes and vapors in welding, laser cutting processes.

-

Pneumatic transport systems for bulk materials:

- Purification of air from dust generated during transport of bulk materials (e.g., grain, cement, granules).

- Ensuring occupational health and safety in areas where pneumatic transport is present.

-

Food industry:

- Extraction of dust and contaminants in food production processes (e.g., grain milling, sugar production, product packaging).

- Ensuring cleanliness and hygiene in food production facilities.

-

Other manufacturing industries:

- Pharmaceutical industry: air purification in drug manufacturing processes.

- Chemical industry: removal of dust and pollutants in chemical processes.

- Woodworking industry: dust extraction in woodworking processes.

Additional application possibilities:

- Removal of dust from technological processes: The filter cyclone can be used to remove dust generated in various types of technological processes, such as grinding, polishing, cutting, drilling.

- Improving air quality at the plant: The filter cyclone contributes to improving air quality in the workplace, which has a positive impact on the health and safety of workers.

- Supporting compliance with environmental standards: Filtrocyclone helps meet environmental standards for dust and air emissions.

- Flexible customized solutions: The manufacturer offers the ability to manufacture non-standard equipment for special customer orders, allowing the Filtrocyclone to be tailored to individual needs.

It is worth noting that the Filtrocyclone is a versatile device that can be used in many different industries and production processes. Its main purpose is to clean the air of dust and pollutants, which contributes to improving the quality of the working environment and the efficiency of production processes.

Quality Guarantee:

We provide a 36-month warranty covering the entire device, which underscores our confidence in the reliability and durability of the product.

Contact us today to learn how Filtrocyclone can optimize your company’s processes and contribute to a cleaner, more efficient work environment.

Technical specification

| – filtration area | 5÷100 m² |

| – number of sleeves | 30 pcs. -120pc. |

| – sleeve diameter | d=120mm |

| – sleeve length | 1000mm |

| – unit load of the filter fabric | 1-6m³/min/ m² |

| – filtrocyclone resistance | 1000-1500Pa |

| – max. concentration of dust in the air supplied to filtrocyclone |

300g/ m³ |

| – dust removal efficiency | 99,8% |

| – air demand needed for sleeve regeneration | 100-250 l/min |

| – compressed air pressure | 0.6÷1 MPa |

| – valve opening period | 0,1 – 0,5 s |

| – Pulse interval adjustment range | 5-60 s |

| – temp range. work | 0-60º C |

| – overall dimensions length x width x height | 2030x1685x3194 |

The size of the machine is adapted to the needs of a large line.

Technical project