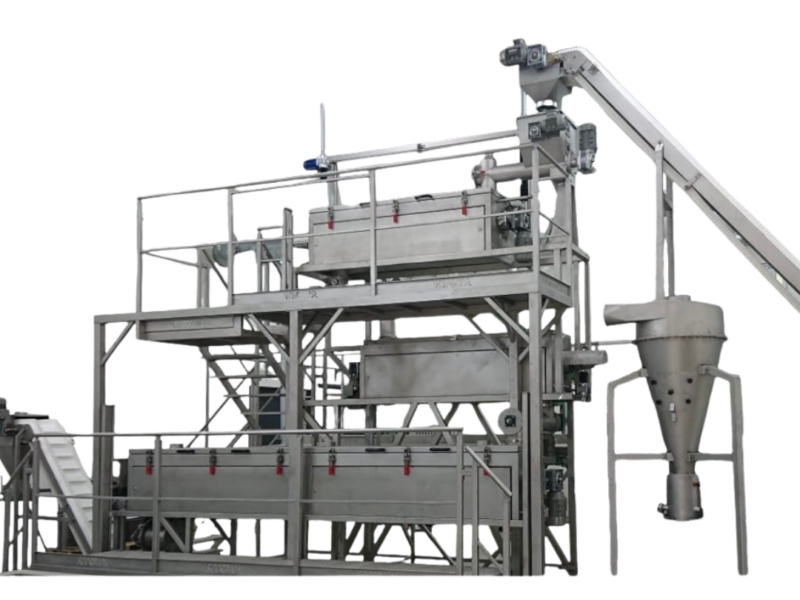

STERILIZER for continuous operation 5 tons

Permanently destroys microorganisms, including spore forms, such as bacteria, fungi, yeast, mold.

High microbiological purity. Allows sterilization of different types of products: ground (e.g., paprika, nutmeg, cloves, etc.), cut (e.g., herbs, fix type fraction, herb thresh, grated), and whole (e.g., peppercorns, allspice, marjoram, etc.).

The sterilization process involves preheating the product, to a temperature of approx. 90°C. From the infeed feeder, the goods enter the sterilizing chamber where they come into direct contact with dry steam (about 130ºC), and then go into the cooling chamber. In the next stage, the raw material is transported to a drying chamber in which the material is thoroughly dried by injecting warm air.

All chambers have infinitely adjustable speed of material movement.

The final stage is bagging in big bags or sacks.