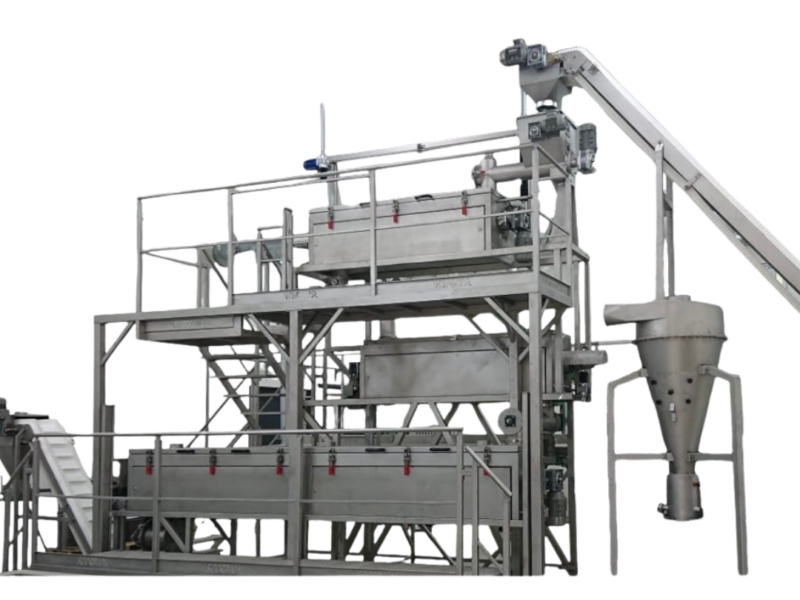

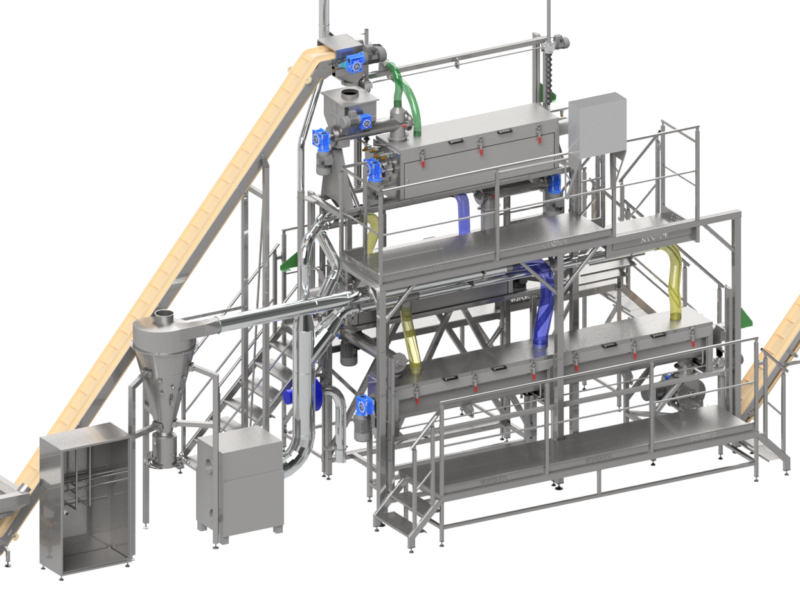

Chamber sterilizer various sizes

Sterilizer is used to destroy microorganisms, including spore forms, such as bacteria, fungi, yeast and mold. The sterilization process guarantees microbiological purity of ground (e.g. ground bell pepper, ground nutmeg, ground cloves, etc.), cut (e.g. cut herbs, fix-type fraction, herb thresh, grated herbs), and whole (e.g. grained pepper, allspice, marjoram, etc.) products. The sterilization process involves preheating the commodity to a temperature of about 90°C then introducing it into a sterilizing chamber in which it is treated with dry steam at a temperature of about 130°C. By smoothly adjusting the speed of the mixer, we control the length of the process. The next step is to cool the product and transport it to the drying chamber.

All chambers have infinitely adjustable speed of material movement.

The final stage is bagging in big bags or sacks.

Technical specification

| performance | ca. 1t-2t/8h |

| power requirement (without steam generator) | ca. 30 kW |

| weight | 2000 kg |

| available steam generators | Gas, fuel oil, electric generators |